Li-ion battery events happen rarely, but when they do occur they are well publicized, costly, and can result in the loss of expensive equipment, facilities, and in the worst case, human life.

Lithium ion battery failures are a sore discussion point for the battery industry. Their energy storage properties are unrivaled, but their advantageous properties also have their vices. Li-ion battery events happen rarely, but when they do occur they are well publicized, costly, and can result in the loss of expensive equipment, facilities, and in the worst case, human life.

Battery failures are present across all industries that use li-ion technology. There is a well-publicized event in every industry implying there is a fundamental safety issue that needs to be addressed. A positive discussion can stem from these failures. As an industry, it is necessary that we learn from these mistakes so that these faults can be avoided in the future.

1. Galaxy Note 7 double recall

(market: consumer electronics)

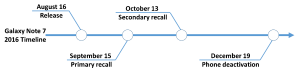

Samsung’s release of the Galaxy Note 7 in August 2016 is fresh in everyone’s mind when it comes to lithium ion battery disasters in the consumer electronics market. The scale of the recall is one reason to make it #1 on this list of top lithium ion battery failures, but the occurrence of the secondary recall solidifies it as the top contender for battery failures.

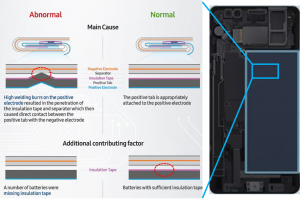

The primary recall occurred on September 15, 2016 with 1 million phones being recalled and 66 reports of battery failures between August 16 and September 15. These failures were attributed to a manufacturing defect causing bent cathodes. After the primary recall and the phones had been shipped back to the customers an additional 23 reports of battery failures occurred. This caused a secondary recall of all Galaxy Note 7 phones on October 13 which was attributed to another manufacturing defect resulting from abnormal ultrasonic welding burrs. All phones were later deactivated on December 19 to avoid further liability issues with phones not sent back during the recall. Depictions of the root causes are shown in the following figures, in their respective order (first picture was primary recall root cause, second picture was secondary recall root cause).

The results of these fires caused bodily harm to several people and even more property damage reports were filed. There are several things to be learned from this failure:[/vc_column_text][vc_column_text]

•Battery manufacturing needs to have rigorous inspection

•Lithium ion battery manufacturing steps need to be well documented and well understood by regulatory and certification bodies to understand how and why particular steps will be vulnerable to causing failure

•Lithium ion battery solutions can never be rushed

2. UPS Airlines Flight 6

(market: shipping)

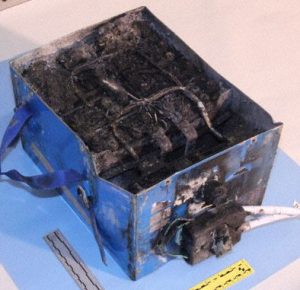

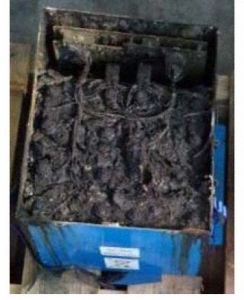

On September 3, 2010 a Boeing 747-400F cargo airplane traveling from Dubai and Cologne developed an in-flight fire with the fumes and subsequent crash resulting in the death of the two crew members on the plane. The crash was attributed to an autoignition of the cargo which contained 81,000 lithium ion battery cells.

On September 3, 2010 a Boeing 747-400F cargo airplane traveling from Dubai and Cologne developed an in-flight fire with the fumes and subsequent crash resulting in the death of the two crew members on the plane. The crash was attributed to an autoignition of the cargo which contained 81,000 lithium ion battery cells.

During the battery failure, the pilots decided they could turn around and make it back to Dubai’s airport instead of landing at the nearest runway. They soon initiated fire suppression and depressurized the cabin. FAA protocol during a fire on a cargo airline is to depressurize the cabin above 20,000 feet to starve the fire of oxygen as well as initiate fire suppression. It is likely that at the point of initiating fire suppression and cabin depressurization, the lithium ion battery fire had developed into a thermal runaway state and propagation had already started to occur to other cells. Lithium ion batteries have the ability to create their own oxygen which meant that depressurizing the cabin was of no help to mitigating the fire and the fire suppression system was not properly designed to mitigate lithium ion battery failures. The pilots lost vision and could not properly land the airplane which caused in a crash landing and the death of both crew members.

During the battery failure, the pilots decided they could turn around and make it back to Dubai’s airport instead of landing at the nearest runway. They soon initiated fire suppression and depressurized the cabin. FAA protocol during a fire on a cargo airline is to depressurize the cabin above 20,000 feet to starve the fire of oxygen as well as initiate fire suppression. It is likely that at the point of initiating fire suppression and cabin depressurization, the lithium ion battery fire had developed into a thermal runaway state and propagation had already started to occur to other cells. Lithium ion batteries have the ability to create their own oxygen which meant that depressurizing the cabin was of no help to mitigating the fire and the fire suppression system was not properly designed to mitigate lithium ion battery failures. The pilots lost vision and could not properly land the airplane which caused in a crash landing and the death of both crew members.

Many things can be learned from this awful event, including:

•Educating the pilots on the extent and severity of lithium ion battery failures

•Protocols designed specifically for lithium ion battery shipments

•Mitigation methods of lithium ion battery failures built into cargo planes

•Specific equipment should be designed and provided which can provide early warning of lithium ion battery failures on airplanes

3. Boeing 787 Dreamliner

(market: aviation)

On January 7, 2013 the lithium ion battery used for auxiliary power and on January 16, 2013 the lithium ion battery used for main power experienced thermal runaway. Both of these occurrences were within a Boeing 787 dreamliner airplane. The battery module, which contained eight 75 Ah cells, contained a single cell that suffered an internal short circuit that propagated to the surrounding cells, causing a large amount of smoke to emanate throughout the airplanes and causing emergency landings.

On January 7, 2013 the lithium ion battery used for auxiliary power and on January 16, 2013 the lithium ion battery used for main power experienced thermal runaway. Both of these occurrences were within a Boeing 787 dreamliner airplane. The battery module, which contained eight 75 Ah cells, contained a single cell that suffered an internal short circuit that propagated to the surrounding cells, causing a large amount of smoke to emanate throughout the airplanes and causing emergency landings.

The events caused the FAA to ground all 787 Dreamliners until a more adequate battery system could be found. The cost of all of these models being grounded cost Boeing $1.1 million dollars per day.

The events caused the FAA to ground all 787 Dreamliners until a more adequate battery system could be found. The cost of all of these models being grounded cost Boeing $1.1 million dollars per day.

Three entities took blame for the event, including Boeing, the FAA, and the manufacturers of the lithium ion batteries, GS Yuasa.

The things to be learned from this event include:

•Lithium ion battery systems should always be designed for the worst-case scenario

•Early detection technologies should be in place so the pilots are responding to the battery failures significantly before smoke generation

4. GM Battery Lab Explosion

(market: R&D)

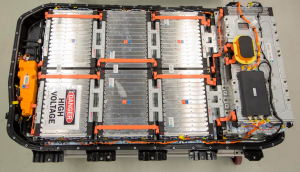

GM’s electric car division has employed several car models such as the Chevrolet Spark EV, the Volt, and others, with the Chevrolet Bolt being released in 2017. A competitive market has brought electric cars to the average consumer in modern times. The lithium ion battery is a large component as to why these electric vehicles are able to be so price competitive.

In April 2012, GM had a severe battery explosion in one of their battery testing labs in Warren, Michigan. The battery explosion caused injury to several employees and caused at least 80 people to evacuate adjacent rooms to the battery testing lab.

The explosion reportedly dislodged and ejected a testing lab door that was 8 inches thick. The cause of the explosion was initially unknown, but later GM stated that there was a release of battery off-gassing compounds that were unaccounted for and accumulated in the testing lab. There was a spark or autoignition of the off-gassing compounds, which are highly flammable, that caused the powerful explosion.

Below is a list of things to be learned from this event:

•It is necessary that all personnel managing or operating equipment that is relevant to a battery failure must be aware of all stages of a lithium ion battery failure

•Having the proper sensing technologies in place to detect all stages of a battery failure, including the initial stages of battery off-gassing

•Having the proper mitigation techniques in place for preventing the accumulation of battery off-gassing compounds (such as having the proper equipment to increase ventilation, etc)

While li-ion battery events are rare, they do happen. By recognizing this, we can take the necessary steps to improve our battery safety, handling, and usage, making the world a safer place. If you need help getting started, contact our lithium ion battery safety experts at info@liiontamer.com for a free battery safety consultation.

Let us help make your technology safer. | |

|---|---|

Contact us for a free consultation with our battery experts and discover ways to improve the safety of lithium ion batteries in your specific application. | |