OUR BRANDS

Safety of large format lithium ion battery system is paramount. The proliferation of battery systems in safety critical applications such as marine, aviation, residential and automotive means that the margin for error is extremely small. A single safety incident in these markets could slow the adoption of lithium ion batteries which have proven to be valuable to meet today’s rigorous energy demands.

Li-ion Tamer® is a new line of products being designed by Nexceris to make batteries safer. Our approach provides unique information about the condition of the battery through monitoring for off-gassing event from the cells. This approach can provide the early warning necessary to take action to prevent a battery fire in your system.

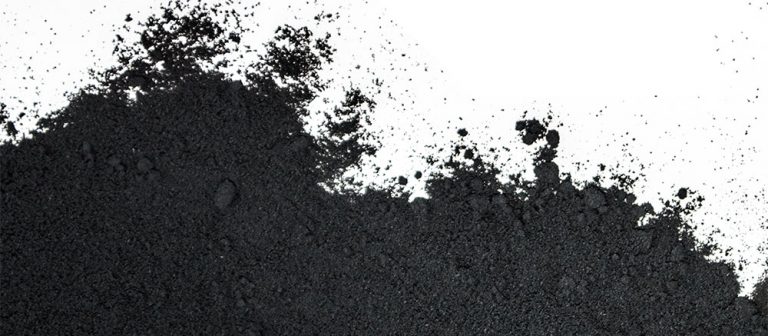

fuelcellmaterials was established in 2000 as a wholly owned division of Nexceris to commercialize innovative ceramic materials technology and products. These technologies and products are suited to the developing of solid oxide fuel cells (SOFC) and fuel processing markets which include such items as: test fixtures, powders, pastes catalysts and components.

fuelcellmaterials is backed by its dedicated staff of material scientists and engineers who deliver high quality materials and assist in helping our clients meet all of their needs. This high level of expertise allows our staff to quickly and accurately tailor our powders and components to fit the needs and processes of our clients. These changes can be as simple as a physical property change or as complex as streamlining a material to work with specific applications.

Adena Power is a new business from Nexceris, and is dedicated to the commercialization of our new sodium solid-state battery. We are proud to be on the cutting edge of new technologies that provide safer, longer duration and lower-cost energy storage.

Adena Power’s sodium solid-state battery technology was developed by the dedicated team at Nexceris to address the need for a lower cost, longer duration, and safe energy storage solution. The technology addresses the shortcomings of Li-ion batteries, is based on an intrinsically safe battery chemistry, and is made from low-cost, sustainable domestic raw materials eliminating supply-chain disruptions and providing an alternative energy storage solution for the electrical grid. This technology has been supported by the U.S. Department of Energy (DOE) through a Small Business Innovation Research (SBIR) contract.

HeatPath™ revamps chemical reactors for carbon constrained economies.

We make chemical reactors more productive and energy efficient.

Collaborative Catalyst Solutions – When coated on HeatPath™, standard catalysts achieve new performance. Collaborative assessments hasten discovery and deployment.

Innovative Catalysts & Reactors – HeatPath™ catalysts move heat differently, making novel formulations and small, simple, reactor designs economically viable.

Licensing & Supply Relationships – Over a decade of experience providing flexible licensing, manufacturing, & demonstration solutions to the chemical industry.

In 2010, NTM Sensors was formed as a business unit of Nexceris to actuate our vision of providing specialized sensing systems for these neglected markets, and provide better sensing options to manufacturers. Through our extensive work in emerging technologies and environmental markets, we recognized a large deficiency in quality safety sensors and monitoring systems suited for these markets. For such tailored markets, like the ones in which we work, you need tailored products. So, we resolved to create innovative and highly selective sensors designed specifically for the advanced technologies and environmental markets in which we were working.

NTM Sensors leveraged its unique chemi-resistive sensing technology to launch its initial product – the NTM SenseH2® hydrogen sensor. It has since produced the NTM SenseH2®-R hydrogen sensor and has several more products in the works.

Nexceris Updates

What are the Benefits and Best Applications of Cathode Powders? A Closer Look at LSM20-HP, LSC, and PNO

Cathode powders are materials that can be used in various electrochemical applications, such as solid oxide fuel cells (SOFCs), solid oxide electrolysis cells (SOECs), gas sensors, and more. Due to their unique properties and performance characteristics, Lanthanum Strontium Manganite (LSM20-HP), Lanthanum Strontium Cobaltite (LSC), and Presidium Nickel Oxide (PNO) are beneficial materials.

Nexceris and FCM attending H2 + FC EUROPE 2024

Nexceris and Fuel Cell Materials (FCM) are excited to participate in Hydrogen + Fuel Cells (H2 + FC) EUROPE, Europe’s largest trade fair for hydrogen and fuel cells. H2 + FC EUROPE offers a unique combination of exhibitions, two forum areas, and networking events to promote synergy and cross-industry cooperation between different technologies dedicated to solving global energy challenges.

National Lab Testing Demonstrates Value in Early Detection

Sandia National Laboratory recently conducted third-party testing to determine the state of stability of lithium-ion (Li-ion) batteries. Li-ion Tamer (Gen2 system) was included in the testing and demonstrated good results for its ability to improve Li-ion battery safety through off-gas detection.