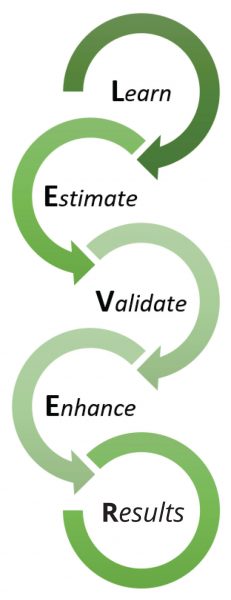

THE LEVER PROCESS

The LEVER Process is our proven collaboration method, which utilizes your technology and Nexceris’ expertise, to allow our partners move to faster to commercialization. Using LEVER, Nexceris has the ability to prove product concepts on lab scale equipment before moving to larger quantities. We keep volume manufacturing in mind to develop scalable processes for our partners.

Whether you are sourcing materials from us or utilizing our products for the advancement of energy and environmental projects, the LEVER process is our proven method for collaboration to help you reach your goals.

WHAT VALUE NEXCERIS BRINGS TO EACH CUSTOMER PROJECT THROUGH LEVER:

- Less investment of equipment and technology

- Use the skills of our design, engineering, materials science teams to complement your existing team

- Screen a large variety of ideas to identify the best

- Delegate tasks to Nexceris to save time

- Focus more on R&D and commercialization and less on creating the processes

- 25 years of experience with advanced energy

- Ability to identify critical customer requirement

- 56,000 sq. ft small and pilot manufacturing capabilities

WHO WE USE LEVER WITH:

Startups

Demonstrate their technology concept

Benefits

- Less investment of equipment and technology

- Accelerate development and validation

- Get to market faster

Fortune 500 Companies

Expand capabilities of their internal groups

Benefits

- Empowers individuals to think outside of organizational limitations

- Expedites process from years to months

- Workforce is better utilized

- More efficient processes are established

National Labs and Universities

Accelerate results faster to secure next round of government funding

Benefits

- Utilize a vertically integrated product developer

- Gain extensive in-house testing validation

- Move more quickly from R&D to commercialization

NEXCERIS’ PROVEN METHOD TO SAVE TIME AND RESOURCES

LEARN – Nexceris works with your team to learn your needs and requirements.

ESTIMATE – Nexceris estimates the product value, using production scale models of the envisioned process to increase production.

VALIDATE – Nexceris validates the recommended process through lab-scale tests and delivery of material for testing.

ENHANCE – Nexceris enhances the value of the work by confirming process reproducibility and identifying process control limits.

RESULTS – Nexceris reports the revised cost model and the best remaining opportunities for process improvement.

LEARN MORE ABOUT LEVER BY READING OUR CASE STUDIES

Protective Coating Technology Transfer Case Study

Metal Air Battery Materials Scale-Up Case Study

Advanced LIB Material Development Case Study

Nexceris Updates

Nexceris sells Li-ion Tamer® lithium-ion battery monitoring products to Honeywell

Nexceris has sold its Li-ion Tamer® off-gas monitoring solution to Honeywell. Li-ion Tamer is the industry’s premier technology for preventing thermal runaway events in lithium-ion

Nexceris Celebrates Earth Day 2025

Nexceris has made the Columbus Business First Fast 50 list. The Fast 50 list consists of the fastest-growing businesses in Central Ohio, showing tremendous growth year after year.

Nexceris Honored to Make 2024 Fast 50 List

Nexceris has made the Columbus Business First Fast 50 list. The Fast 50 list consists of the fastest-growing businesses in Central Ohio, showing tremendous growth year after year.