ADVANCED BATTERY MATERIALS

Battery Technologies

As sustainability-minded manufacturers, government/regulatory bodies and private entities look to a Net Zero future, energy storage solutions and innovations are urgently needed.

Nexceris is proud to be on the cutting edge of providing battery materials that support clean energy storage.

Battery Materials

At Nexceris, we have significant experience and expertise in researching and developing the next generation of lithium-ion batteries. In fact, Nexceris is leading a multi-year project funded by the Department of Energy (DOE) to develop cathode materials for the next generation of lithium-ion batteries. We are also exploring and generating high-voltage spinel cathodes and cobalt-free cathodes.

We want to know what battery challenges you have and how can we assist you.

Advanced Energy

Some current constraints are happening with the performance of lithium-ion batteries in electric vehicles such as low-driving range, high-purchase and warranty costs.

Some of the ways we are looking to explore:

- High voltage spinel cathodes that are able to take the stress of the cycling process

- Cobalt-free cathodes to reduce dependency on cobalt itself and cost reduction

- Since we are a company dedicated to ceramics, there has been a need in certain industries for other types of batteries besides lithium-ion.

Nexceris stays on the cutting edge of technology to assist advanced energy markets such as:

Metal-Air Batteries

Nexceris produces perovskite and other oxide-based materials for the air electrode for metal-air batteries. With our extensive experience in spin-on carbon (SOC) materials, we are a good fit for creating these new materials.

Cobalt-free Li-ion Battery Materials

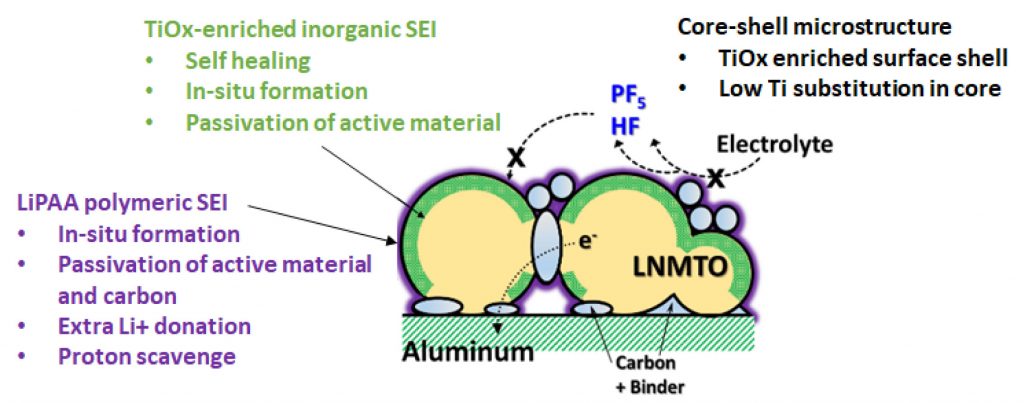

Nexceris is developing a cobalt-free cathode to correct the spinel fail and poor cycle life associated with high-voltage LiNi0.5Mn1.5O4 (LNMO).

Nexceris focuses on Ti-substituted LiNi0.5Mn1.5-xTixO4 to improve cycle life and longevity by forming solid–electrolyte interphase (SEI) to passivate the cathode surface.

THE LEVER PROCESS

Battery Technology

Battery Materials

Solving Problems

Nexceris can help with the entire process from R&D through product launch.

SECURE SUPPLY CHAIN

Nexceris has the ability to prove out product concepts on lab scale equipment before moving to tonnage quantities. We keep volume manufacturing in mind to develop scalable processes for our partners. We also have a strong distribution network to ensure global reach.

Flexible Business Models

Nexceris is open to many working agreements and has experience with licensing, technology transfer, supply agreements and in-house value added manufacturing. We work with our partners to find the best business arrangement for the situation.

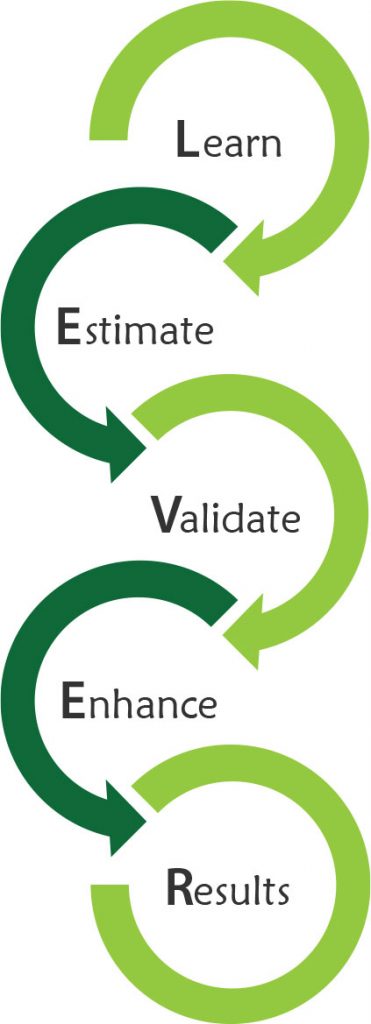

LEVER Process

Our Proven Process Saves Time and Resources

Learn – Nexceris works with your team to learn your needs and requirements.

Estimate – Nexceris estimates the product value, using production scale models of the envisioned process to increase production.

Validate – Nexceris validates the recommended process through lab-scale tests and delivery of material for testing.

Enhance – Nexceris enhances the value of the work by confirming process reproducibility and identifying process control limits.

Results – Nexceris provides actionable results to maximize value for your team.

Nexceris Updates

National Hydrogen and Fuel Cell Day

Everyone at Nexceris is extremely excited for October 8, 2022, because it happens to be National Hydrogen and Fuel Cell Day.

Visit Nexceris at the European Fuel Cell Forum July 5-8 Lucerne

Nexceris, through its fuelcellmaterials group, will be attending the European SOFC and SOE Forum (EFCF) in Lucerne, Switzerland, from July 5-8, 2022.

Nexceris Participating in the 22nd Annual Solid Oxide Fuel Cell (SOFC) Project Review

Nexceris is excited to be presenting at The Department of Energy’s National Energy Technology Laboratory’s 22nd Annual Solid Oxide Fuel Cell (SOFC) Project Review Meeting being held on November 16-18, 2021.