HISTORY

Founded in 1994, Nexceris is an energy company that develops innovative sensor, power generation and catalyst solutions. While technology development for the U.S. Government was the foundation of the company, Nexceris has successfully commercialized solid oxide fuel cell materials and advanced gas sensor product lines in recent years. We currently aim to accelerate commercialization of our pipeline of emerging technologies.

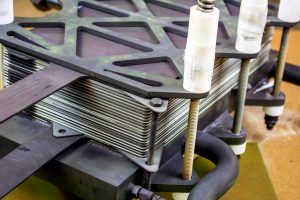

HeatPath™ revamps chemical reactors for carbon constrained economies. We make chemical reactors more productive and energy efficient.

Adena Power is a new business from Nexceris, and is dedicated to the commercialization of our new sodium solid-state battery.

Initiated work on $4 million DoE-sponsored project for development of SOFC and electrolyzer technology.

Formed JDA to commercialize Li-ion Tamer in EVs. In partnership with a Top 3 Global Auto Group.

Formed strategic partnership with Honeywell for global distribution of Li-ion Tamer stationery products.

Signed JDA to develop SOFC solution for e-mobility. In partnership with a Top 10 Auto Manufacturer.

Awarded contract under ARPA-E's INTEGRATE Program to further develop SOFCs.

Signed JDA to develop a NOx Sensor product. In partnership with a Tier-1 Automotive Supplier.

Awarded contract by the Vehicle Technologies Office (DoE) to develop cathode battery materials for next generation Li-ion batteries.

Fuel Cell coating commercialized.

Won multi-million dollar contract for SOFC system development from the Office of Naval Research. In partnership with Northrop Grumman and ATK.

Nuclear Sensor development begins.

H2 Alarm Box launched.

ISO 9001 Certification received.

Developed Li-ion off-gas detection sensor under a Navy-sponsored project. Currently sold under the Li-ion Tamer business unit.

Corrosion coating begins.

Began work on NOx sensors after discovering a new mechanism for NOx detection.

Initiated SOFC stack R&D with joint development agreement ("JDA"). In partnership with Plug Power.

Launched second #2 million project from the NIST Advanced Technology Program for further development in SOFC technology. In partnership with NASA.

Moved to 56,000 sf facility in Lewis Center.

$2 million SOFC project for the National Institute of Standards Technology ("NIST") Advanced Technology Program. In partnership with Hewlett Packard.

Awarded contract from U.S. Department of Energy ("DoE") to establish an electrolyte coating process for solid oxide fuel cells ("SOFC"). Partnership with Siemens Westinghouse.

Nexceris Updates

Nexceris sells Li-ion Tamer® lithium-ion battery monitoring products to Honeywell

Nexceris has sold its Li-ion Tamer® off-gas monitoring solution to Honeywell. Li-ion Tamer is the industry’s premier technology for preventing thermal runaway events in lithium-ion

Nexceris Celebrates Earth Day 2025

Nexceris has made the Columbus Business First Fast 50 list. The Fast 50 list consists of the fastest-growing businesses in Central Ohio, showing tremendous growth year after year.

Nexceris Honored to Make 2024 Fast 50 List

Nexceris has made the Columbus Business First Fast 50 list. The Fast 50 list consists of the fastest-growing businesses in Central Ohio, showing tremendous growth year after year.