RSOC & SOFC TECHNOLOGY

RSOC and SOFC Technology

Advance Your Technology and Accelerate Time to Market

With 30 years of solid oxide experience, Nexceris is the testing, production and commercialization partner you need for acceleration and rapid scale-up.

We collaborate with private and public sector partners to advance Reverse Solid Oxide Cell (RSOC) and Solid Oxide Fuel Cell (SOFC) technologies for power generation, long term energy storage, and grid support.

ROSC technology can be used to help manage the supply and demand of electricity of the electrical grid by switching between Electrolysis mode to generate hydrogen when excess power is available and Fuel Cell mode to generate power when there is additional demand.

SOFC technology is key to and offers many promising attributes, including low materials cost, high-efficiency, fuel flexibility, quiet operation and can be adapted for multiple power generation applications. Nexceris has extensive, decades-long experience in SOFC development which underpins all of our solid oxide capabilities.

Core Benefits:

- Carbon-friendly solutions for power generation, storage, and reversible operation

- Flexibility to advance both R&D and commercialization goals

- Customize our materials sets for your specific application

- Proven collaborative process—LEVER

Our Core Solutions

Currently, Nexceris is focused on solid oxide fuel cell applications related to Power Generation, Reversible for Grid Support and Long-Term Energy Storage.

Power Generation

The original application for Nexcers’ stack was to operate as a Solid Oxide Fuel Cell to generate power. Leveraging the attributes of the FlexCell, Nexceris’ has tailored the fuel electrode chemistry for sulfur tolerant operation to support military applications which require the use of logistic fuels (JP-5, JP-8, etc). Our fuel electrode chemistry can also be tailored to operate by internally reforming light hydrocarbons such as methane and natural gas for applications requiring high efficiency.

The original application for Nexcers’ stack was to operate as a Solid Oxide Fuel Cell to generate power. Leveraging the attributes of the FlexCell, Nexceris’ has tailored the fuel electrode chemistry for sulfur tolerant operation to support military applications which require the use of logistic fuels (JP-5, JP-8, etc). Our fuel electrode chemistry can also be tailored to operate by internally reforming light hydrocarbons such as methane and natural gas for applications requiring high efficiency.

Nexceris has focused its SOFC stack development work on military applications where high power density, high efficiency, system simplicity and fuel flexibility are desired. A key Nexceris accomplishment was the development of anode technology with unprecedented tolerance to sulfur, which provides a path for SOFC operation on JP-8 fuels without desulfurization. Another important attribute of the Nexceris stack technology is the ability to operate at high single-pass fuel utilization – this greatly simplifies the system design. What follows are two recent examples of ongoing Nexceris SOFC stack technology development.

Nexceris is working with the U.S. Army (TARDEC) on a project aimed at the design, development and demonstration of a 5-kW scale, power dense and sulfur tolerant solid oxide fuel cell stack for military ground vehicle auxiliary power units. Employing Nexceris’ sulfur tolerant stack technology, the stack developed on this project will enable development of an SOFC system capable of operating with JP-8 logistic fuel.

Nexceris is working with the U.S. Air Force (AFRL) on a project aimed at design, development and demonstration of a high power density solid oxide fuel cell stack for military power applications including unmanned aerial systems, unmanned ground systems, vehicle auxiliary power and mobile power generation. The project targets a 2-kW scale SOFC stack with a gravimetric power density of 500 W/kg.

Long-term Energy Storage

Nexceris technology development has focused on the running of its stack in electrolysis mode by tailoring the FlexCell oxygen electrode chemistry. This type of operation is used to efficiently produce hydrogen or carbon monoxide from steam and carbon dioxide by consuming power. The production of these chemicals can be used as the precursor to generate high energy density compounds such as methane, ammonia, methanol, or hydrogen which can be stored for later use. Coupled with either a renewable energy source or a plant where high temperatures are available. By converting power to these value-added chemicals energy can be stored for an indefinite amount of time.

Nexceris technology development has focused on the running of its stack in electrolysis mode by tailoring the FlexCell oxygen electrode chemistry. This type of operation is used to efficiently produce hydrogen or carbon monoxide from steam and carbon dioxide by consuming power. The production of these chemicals can be used as the precursor to generate high energy density compounds such as methane, ammonia, methanol, or hydrogen which can be stored for later use. Coupled with either a renewable energy source or a plant where high temperatures are available. By converting power to these value-added chemicals energy can be stored for an indefinite amount of time.

Reversible Operation for Grid Support

The final macro application of Nexceris stack technology is for reversible operation. This type of operation requires the stack to run both in Fuel Cell and Electrolysis modes. Again, Nexcers can optimize the FlexCell’s electrode chemistries to support operation under these conditions. our stack can be used to help manage the supply and demand of electricity of the electrical grid by switching between Electrolysis mode to generate hydrogen when excess power is available and Fuel Cell mode to generate power when there is additional demand. Successful systems developed with this operational concept can greatly help support grid resiliency. Contact one of our experts to see how we can tailor our stack to fit your reversible operation needs.

The final macro application of Nexceris stack technology is for reversible operation. This type of operation requires the stack to run both in Fuel Cell and Electrolysis modes. Again, Nexcers can optimize the FlexCell’s electrode chemistries to support operation under these conditions. our stack can be used to help manage the supply and demand of electricity of the electrical grid by switching between Electrolysis mode to generate hydrogen when excess power is available and Fuel Cell mode to generate power when there is additional demand. Successful systems developed with this operational concept can greatly help support grid resiliency. Contact one of our experts to see how we can tailor our stack to fit your reversible operation needs.

CALL US TODAY

AT 614.842.6606 TO SPEAK WITH ONE OF OUR SOFC EXPERTS

Fuel Cell System Presentation

Fuel Cell News

National Hydrogen and Fuel Cell Day

Everyone at Nexceris is extremely excited for October 8, 2022, because it happens to be National Hydrogen and Fuel Cell Day.

MARKET APPLICATIONS

GOVERNMENT & DEFENSE

POWER & ENERGY

Nexceris Third-Party Testing Capabilities

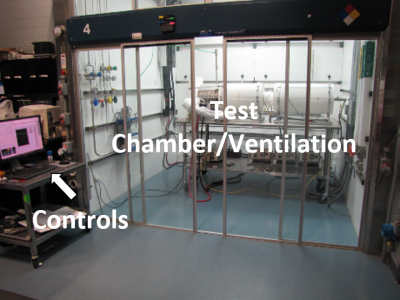

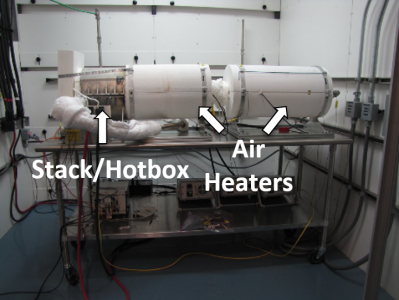

Nexceris has worked closely with government agencies (CCDC-GVSC and NASA-GRC) to help establish the capability of testing our stack technology at their site. This enables the ability for the synergistic development and validation of our stack technology by some of the leading experts in the field of solid oxide fuel cells. [ARMY Contract No. W56HZV-14-C-0053]

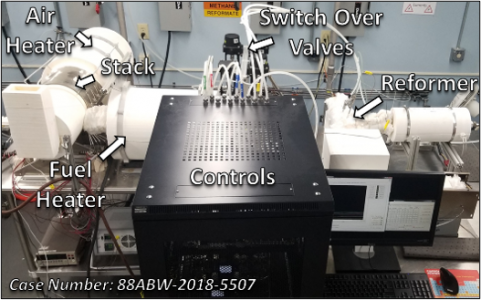

Fuel Cell Lab at CCDC-GVSC with Nexceris’ stack/hotbox equipment

The test apparatus is capable of testing stacks up to 5 kW in scale

Nexceris Development Capabilities

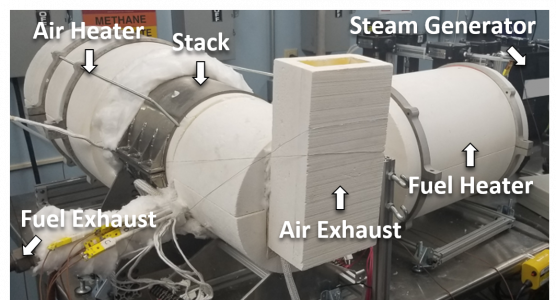

Nexceris - Going from TRL-4 to TRL-5

Coming soon! Nexceris is currently in the process of advancing our stack technology from TRL 4 to 5 by building and demonstrating operation in a thermally integrated system.

TRL-4

TRL-5

Nexceris Updates

National Hydrogen and Fuel Cell Day

Everyone at Nexceris is extremely excited for October 8, 2022, because it happens to be National Hydrogen and Fuel Cell Day.

Visit Nexceris at the European Fuel Cell Forum July 5-8 Lucerne

Nexceris, through its fuelcellmaterials group, will be attending the European SOFC and SOE Forum (EFCF) in Lucerne, Switzerland, from July 5-8, 2022.

Nexceris Gives Invited Keynote Presentation at the TMS 2022 Annual Meeting

Nexceris was excited to present at the TMS 2022 Annual Meeting & Exhibition held on February 28-March 3, 2022 in Anaheim, California.