This past month our Director of Material Science Dr. Neil Kidner presented at the 43rd International Conference and Exposition on Advanced Ceramics and Composites (ICACC 2019) in Daytona Beach, Florida. This opportunity to bring together experts on fuel cells and ceramic technologies provided an excellent backdrop to present on some of our recent projects, including the importance of long-term accelerated testing data as shown in the following excerpt from his talk.

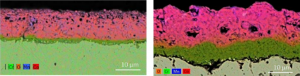

To achieve commercial acceptance, long-term stability testing is critical to demonstrate improved durability of protective coatings. Nexceris has successfully developed a suite of coatings to provide improved high-temperature protection to metallic components used in solid-oxide fuel cells (SOFC). The result of achieving this improvement is to ultimately lower stack and operating costs by increasing the lifetime of the stack and reducing warranty claims. Figure 1 shows the as-processed microstructure of Nexceris’ commercially-available manganese cobaltite (MCO) protective coating for the cathode-side active area of metal interconnects. Through careful control of the powder formulation and coating process, a highly dense and adherent coating can be produced on ferritic stainless-steel substrates.

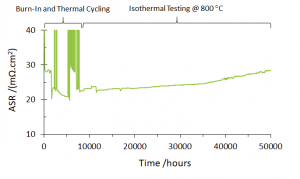

The target service life for stationary SOFCs is 40,000 hours. It is therefore important to demonstrate that the coating is stable over these service lifetimes. As shown in Figure 2, Nexceris has tested an MCO coated sample for 50,000 hours under standard SOFC cathode operating conditions: 800 °C, humidified air with an applied current density of 0.5 A/cm2. The electrical ASR (Area Specific Resistance) of the sample is extremely stable: From the beginning of isothermal stability testing starting around 7,500 hours, the ASR increases by less than 10 mΩ.cm2 over the remaining 42,500 hours of testing.

Figure 3 shows how effective the MCO coating is at restricting native chromia growth at the metal surface. The chromia scale has grown by less than 10-microns. This is confirmed by the minimal increase in ASR seen in Figure 2.

Figure 3 shows how effective the MCO coating is at restricting native chromia growth at the metal surface. The chromia scale has grown by less than 10-microns. This is confirmed by the minimal increase in ASR seen in Figure 2.

The ASR samples were put on test around the same time as my first daughter Emma was born. When we eventually took the sample off test, Emma was six and a half years old! As shown in Figure 4 Emma has grown significantly more over this time than the chromia scale!

This example highlights the obvious fact that long-term testing takes a long time. It is therefore critical to identify accelerated testing methodologies that can provide a quicker assessment of the performance and potential failure mechanisms of a technology. This is key to improving the technology and providing confidence that the product will achieve the required service lifetime. For our coatings, Nexceris has developed a suite of accelerated testing protocols, based on thermal cycling and increased testing temperature. Furthermore, Nexceris has collaborated with Dr. Mark Walter in the Mechanical Engineering Department at The Ohio State University to develop coating lifetime projections based on fracture energy models (S. R. Akanda et al., 2014, Thin Solid Films, 565:237-248).

This example highlights the obvious fact that long-term testing takes a long time. It is therefore critical to identify accelerated testing methodologies that can provide a quicker assessment of the performance and potential failure mechanisms of a technology. This is key to improving the technology and providing confidence that the product will achieve the required service lifetime. For our coatings, Nexceris has developed a suite of accelerated testing protocols, based on thermal cycling and increased testing temperature. Furthermore, Nexceris has collaborated with Dr. Mark Walter in the Mechanical Engineering Department at The Ohio State University to develop coating lifetime projections based on fracture energy models (S. R. Akanda et al., 2014, Thin Solid Films, 565:237-248).

Nexceris would be happy to assist others in the SOFC/SOEC field and find novel ways to accelerate testing, because not everyone has the time to wait five years for results. Please contact us if you are interested and want to hear more information about our coatings technology.