Established SOC Companies

Pivoting Into New Solid Oxide Electrolysis Technologies and Markets is Easier with Innovative Resources

When you have been established in SOC for years, many times it is challenging to determine how your operations and products must pivot to keep up with emerging technologies or new markets. Solid Oxide Electrolysis certainly provide an answer to keeping relevant and innovative in this field. It is often hard to know what the first step is if you are committed to embedded technologies in your systems and restrained by their limitations. But with 25 years of focusing our materials science expertise on creating innovative products that improve the quality, efficiency and safety of energy and environmental systems, this is where Nexceris can help.

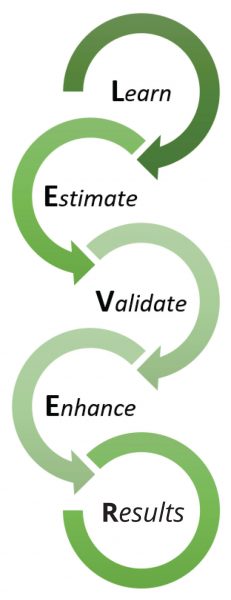

At Nexceris, we understand that SOC developers are trying to make this pivot into new technologies and markets but need further commercial development of their systems to improve performance as well as bring costs down to see more commercial success. Therefore, we use a proven collaboration method with partners of all sizes, called the LEVER Process, which utilizes your technology and Nexceris’ expertise, to allow our partners move to faster to commercialization. For those needing a robust supply chain, we also provide quality materials so you are not reliant on a sole source provider and have more ability to control your production.

Utilizing our expertise in solid oxide fuel cells (SOFC) and electrolysis (SOEC) along with our extensive IP portfolio, we have partnered with major energy companies and manufacturers looking to shift into SOEC. We have helped them improve cell performance through a variety of modifications or scale-up of downselected materials. Looking at the bigger picture, we were able to help reduce costs without performance degradation.

NEXCERIS’ PROVEN METHOD TO SAVE TIME AND RESOURCES

LEARN – Nexceris works with your team to learn your needs and requirements.

ESTIMATE – Nexceris estimates the product value, using production scale models of the envisioned process to increase production.

VALIDATE – Nexceris validates the recommended process through lab-scale tests and delivery of material for testing.

ENHANCE – Nexceris enhances the value of the work by confirming process reproducibility and identifying process control limits.

RESULTS – Nexceris reports the revised cost model and the best remaining opportunities for process improvement.