ALUMILOK

High Temperature Corrosion Protection

The AlumiLokTM coating process is a scalable, cost-effective approach to protect metal components from corrosion in high-temperature applications. Coated stainless steel components exhibit eight to ten times less oxidation, greatly exceeding the performance of other high temperature alloys. AlumiLokTM has been shown to work with a wide range of materials, including ferritic & austenitic stainless steels, Inconel, nickel alloys & copper alloys. AlumiLokTM replicates the traditional aluminization surface microstructure, proving just as effective as the expensive vapor phase aluminization process.

To Learn More About How Our Coatings Can Impact Your Product, Contact Our Coatings Specialists

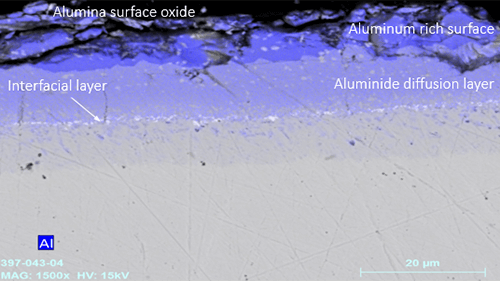

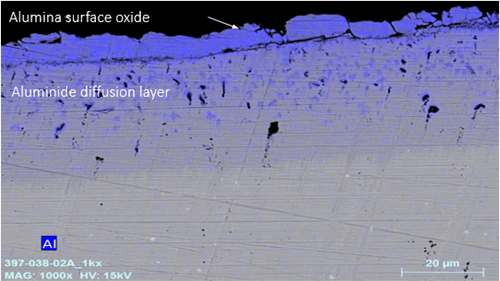

Coating reproduces the microstructure produced by conventional aluminization processes

AlumiLok Microstructure

Aluminide Coating (AlumiLok)

Vapor-Phase Aluminization (VPA)

Substrate: 316 stainless steel

Aluminide coating: standard processing

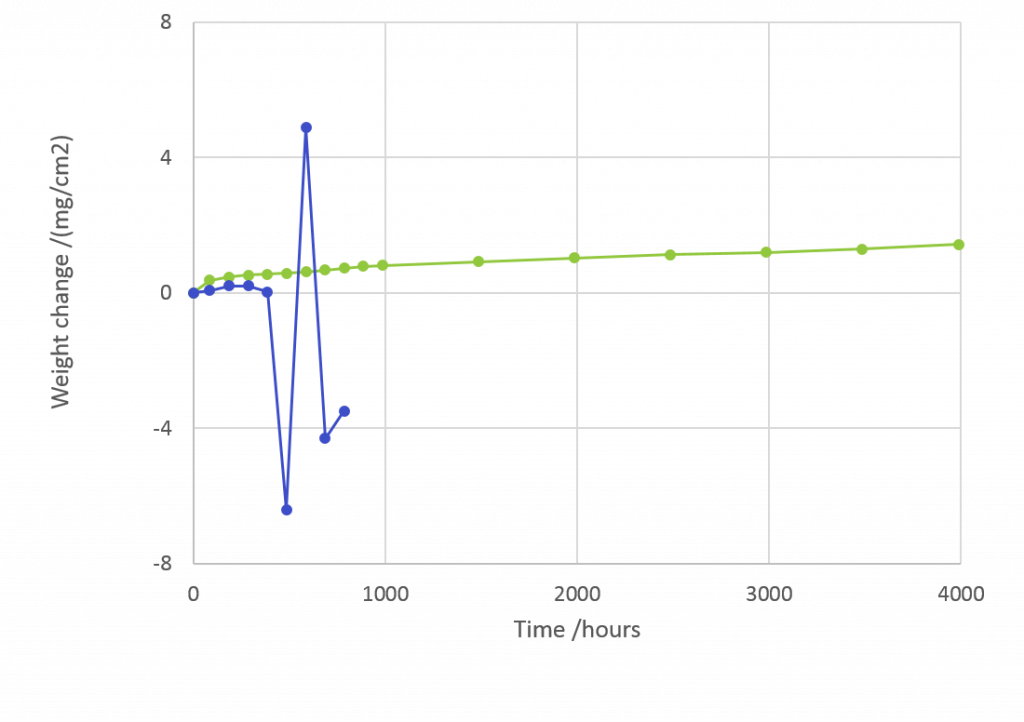

AlumiLok coating significantly improves oxidation behavior of stainless steels

AlumiLok Oxidation Behavior

AlumiLokTM Coated

Uncoated

Substrate: 316 stainless steel Temperature: 900 °C Gas composition: humidified air

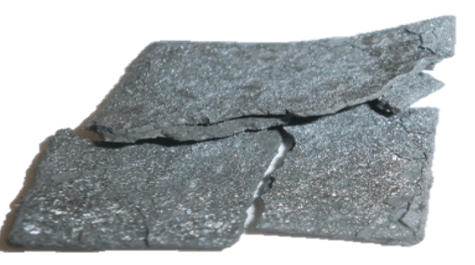

Resistance to coking in high carbon gas streams

AlumiLok Coking Behavior

Uncoated

Coated

Substrate: 316 stainless steel

Exposure time: 100 hours

Temperature: 550 °C

Gas composition: 33 % H2, 30 % CO2, 24.7 % CO, and 12 % CH4

Pressure: 4 psi

Nexceris Updates

Accelerated Testing for Long-Term Results with Solid Oxide Fuel Cells

To achieve commercial acceptance, long-term stability testing is critical to demonstrate improved durability of protective coatings. Nexceris has successfully developed a suite of coatings to provide improved high-temperature protection to metallic components used in solid-oxide fuel cells (SOFC).

Revisiting Nexceris’ Solid Oxide Fuel Cell Advancements from MS&T 2018

Remember MS&T 2018 in Columbus, Ohio? No?! Well, all of us at fuelcellmaterials want you to remember what we talked about and fueled up your brain a bit.

Functional SOFC Interface Coatings Presented at European SOFC & SOE Forum

Nexceris was honored to give a presentation at the 13th European SOFC & SOE Forum on our development of various SOFC interfaces created by aerosol-spray deposition. Our Director of Materials Science, Neil Kidner, recently gave a talk on July 4th at the conference, which is held every two years in beautiful Luzern, Switzerland.