CHROMLOK

Protection of Solid Oxide Fuel Cell (SOFC) Interconnects

The ChromLok process provides long term protection from chromium emission

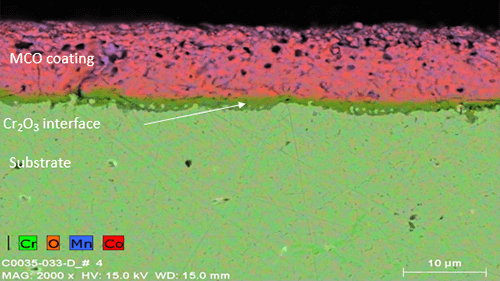

fuelcellmaterials’ innovative ChromLokTM system provides metallic components used in solid-oxide fuel cell systems with the high-temperature protection they need. The ChromLokTM system includes a range of complementary oxide coatings that prevent the release of detrimental chromium species from stainless steels during high temperature operation. Coatings include a manganese cobaltite (MCO) coating, which combines excellent protection with low resistance, ideal for the cathode active-area where electrical conductivity is critical. Additional coatings include non-active, insulating coatings compatible with common seal materials and a Ni-based anode side coating.

To Learn More About How Our Coatings Can Impact Your Product, Contact Our Coatings Specialists

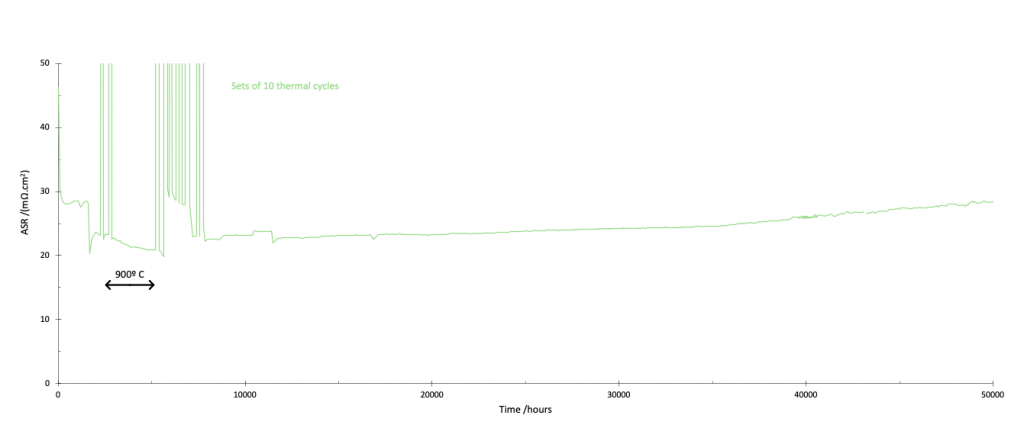

Excellent long term stability for over 50,000 hours demonstrated

Electrical ASR performance of MCO coated ferritic stainless steel

Substrate: AL 441-HP Temperature: 800 °C – 900 °C

Gas composition: humidified air (~ 3 % H2O) Current density: 0.5 A/cm2

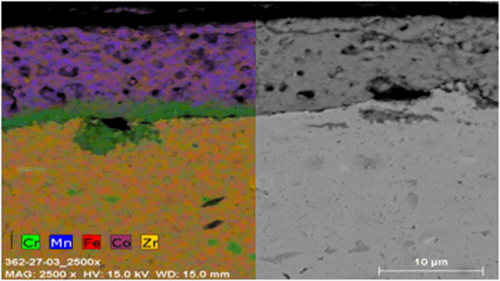

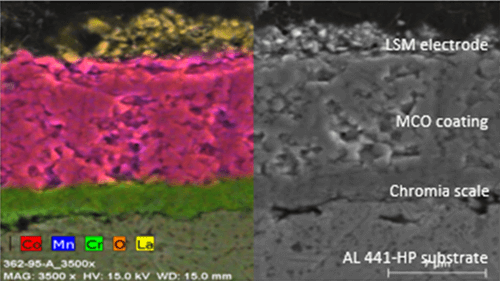

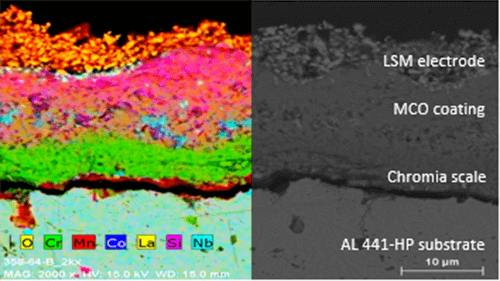

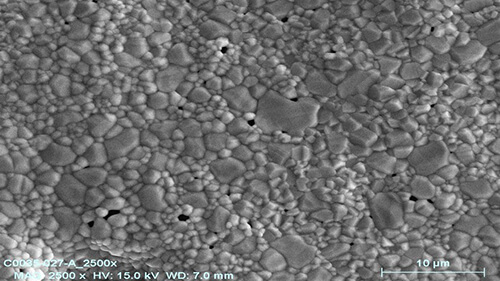

ChromLok Microstructure

After Deposition 800 hrs 800º C >7000 hrs 800ºC/900ºC

Top Down MCO Coating Cross Section MCO Coating

Nexceris Updates

Accelerated Testing for Long-Term Results with Solid Oxide Fuel Cells

To achieve commercial acceptance, long-term stability testing is critical to demonstrate improved durability of protective coatings. Nexceris has successfully developed a suite of coatings to provide improved high-temperature protection to metallic components used in solid-oxide fuel cells (SOFC).

Revisiting Nexceris’ Solid Oxide Fuel Cell Advancements from MS&T 2018

Remember MS&T 2018 in Columbus, Ohio? No?! Well, all of us at fuelcellmaterials want you to remember what we talked about and fueled up your brain a bit.

Functional SOFC Interface Coatings Presented at European SOFC & SOE Forum

Nexceris was honored to give a presentation at the 13th European SOFC & SOE Forum on our development of various SOFC interfaces created by aerosol-spray deposition. Our Director of Materials Science, Neil Kidner, recently gave a talk on July 4th at the conference, which is held every two years in beautiful Luzern, Switzerland.